But this 2002 Polaris 600 Pro X has a mod that slows it down: ski brakes.

Besides the unique brake system, the University of Wisconsin-Platteville (UWP) Clean Snowmobile Challenge (CSC) team’s sled has a flame-throwing exhaust system and direct drive — all in the name of reduced emissions.

Every March, teams of college students from across North America gather at Michigan Tech University’s Keweenaw Research Center in Houghton, Michigan, to compete in the challenge.

Many teams just try to build a snowmobile that’s cleaner and quieter without regard for performance, said UWP CSC Team Captain Eric Koehler. But the Platteville-based team’s strategy was to build a sled that also offered the exhilarating performance that snowmobilers crave.

Power for the team’s sled comes from a Rotax 600 H.O. SDI engine. The team chose the semi-direct injected engine based on the theory that its fuel system creates fewer emissions than a carbureted engine. The theory was proven true, said Koehler, a mechanical engineering major at UWP.

“Our sled was by far the cleanest two-stroke in the competition,” Koehler said. “It was cleaner than some four-strokes.”

The engine is extra clean because of its complex exhaust system. The engine uses the stock pipe. But instead of exiting through the nose-pan, the system routes to the rear like a motorcycle. Exhaust gasses are cleansed in a catalytic converter that’s mounted under the seat.

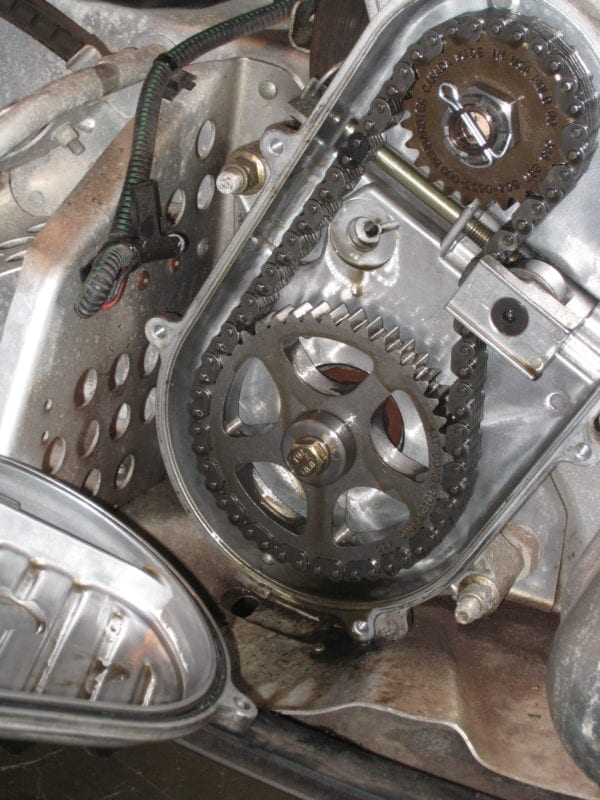

To get the exhaust system en route to the top of the tunnel, the team installed a direct drive system from Radical Machines Inc. This modification cut 12 pounds from the machine and provided space to mount the pipe.

Exhaust gasses flow under a custom aluminum gas tank and into a muffler from a Chevrolet Suburban. The muffler quiets the exhaust note and gives it a unique hum that sounds similar to a jet, Koehler said.

The muffler is attached to a two-stage catalytic converter that burns the exhaust’s hydrocarbons in its first stage. A belt-driven air pump from a Chevrolet Camaro is mounted on the mag end of the engine. It injects oxygen into the converter’s second stage where carbon monoxide is converted to carbon dioxide. At night, a blue flame can be seen shooting from the catalytic converter.

New Trails Inc. had the right seat for the sled. The company’s Extreme NT Flex Seat is hollow on its underside, which provides space for the exhaust system to fit between the seat and tunnel. The team added a thermal barrier from 3M to deflect heat and provide an air gap to assist cooling.

The prototype brake system, compliments of Trinity Mountain Design, consists of dual self-retracting, 2-inch claws that are mounted to the bottom of the skis.

The claws dig into the ground when activated by an auxiliary, handlebar-mounted brake lever; they pop back into the ski bottoms when the lever is released. A mini air-compressor under the hood deploys the claws when the driver squeezes the lever.

In the 2004 Clean Snowmobile Challenge, the ski brakes decreased the sled’s stopping distance 21 percent compared to using only the stock hydraulic brake package. That won the CSC’s award for the best brake system. Unfortunately for the UWP team, the braking event was not part of the 2005 Clean Snowmobile Challenge. The team won several other parts of the competition, though, including acceleration and handling.

Competition officials said the sled was one of the best performing sleds at the 2005 clean snowmobile challenge, according to Koehler.